a global reference

in electric propulsion

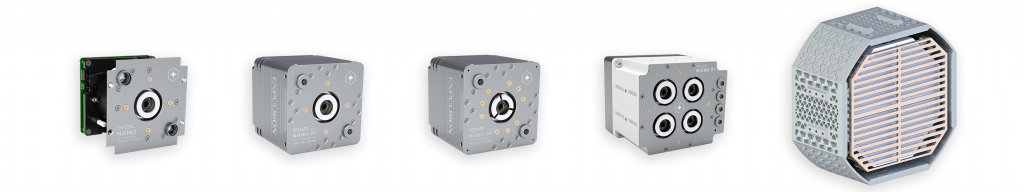

Product Portfolio

OR

Search our knowledge base to learn more about our technology.

Production.

Means.

Perfection.

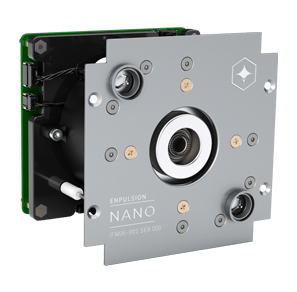

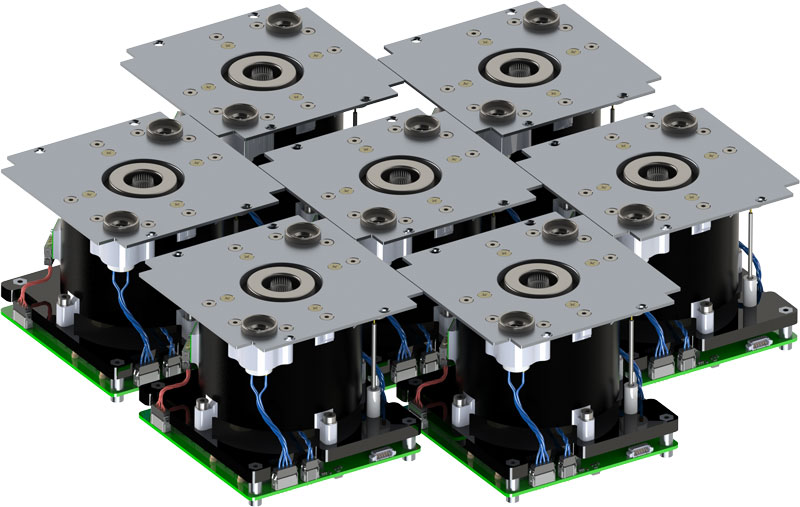

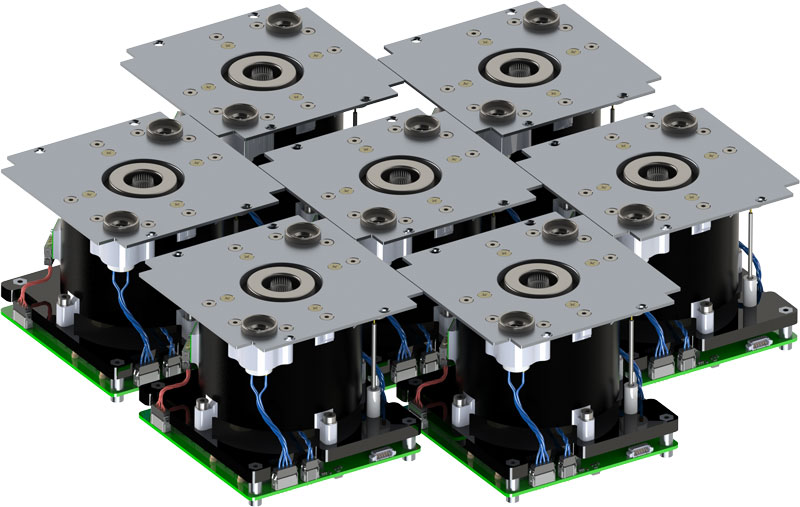

We have successfully introduced a serial production of a high-performance electric propulsion technology. Based on value stream analysis, a scalable production line design has been implemented that scales to mega constellation production rates. Lean manufacturing philosophy allows to implement a product lifecycle philosophy that combines New Space agility with heritage quality processes, while providing high customer value in terms of product performance, cost reduction and short cycle times.

thrusters

in space

Thrusters

delivered worldwide

accumulated years

of on-orbit operations

> 85% efficiency

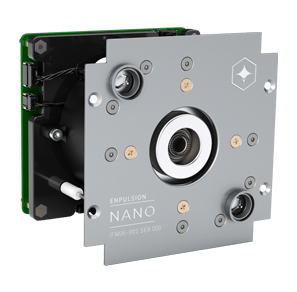

Compact

ESA Science Missions

Powerful

building blocks

for customization

Modular

lead times

> 85% efficiency

Easy and fast just Plug & Play

Compact

ESA Science Missions

Powerful

building blocks

for customization

Modular

lead times

COMMERCIAL

CUSTOMERS

ENPULSION products are tested and proven in orbit.

RECURRING

ORDERS

High customer satisfaction leads to the building of trust and long-term partnerships.

CONSTELLATION

CONTRACTS

Scalability and consistent quality of ENPULSION products make them the perfect solution for large-scale projects.

Join the movement

& get your thruster

Updates

Vienna, Austria and Sofia, Bulgaria, 27 November – EnduroSat and ENPULSION signed an contract for the delivery of 100 fully integrated electric propulsion systems. The first 30 to are to be delivered in the next 12 months, including an initial batch due by the end of year.

Vienna, Austria, and Noordelijk, Netherlands, 11 November 2024 – ESA and ENPULSION signed a contract to further develop the performances of the NextGen FEEP MICRO R³ Thruster for a total of € 4 Million in funding.

Vienna, April 30, 2024 – ENPULSION hosted its first official event at its new head office and production facilities, located at the Vienna Airport, Austria, the move – tripling the company’s facility size to 4.000 sqm as well as its potential yearly production and innovation capacity – marking a decisive step towards unconstrained in-space mobility.